Modur stepper magnet parhaol 35BYJ46 Modur stepper 35mm gyda blwch gêr

Disgrifiad

Mae'r 35BYJ46 yn fodur magnet parhaol 35 mm o ddiamedr gyda gerau.

Mae gan y modur gymhareb gêr o 1/85 ac mae'n fodur camu 4 cham un polyn safonol gyda blwch gêr cymhareb gêr 85 ar ei ben, felly mae'r ongl gam yn 7.5°/85.

Mae cymhareb gêr blwch gêr o 25:1, 30:1, 41.6:1, 43.75:1 hefyd ar gael i gwsmeriaid ddewis ohonynt.

Mae'r modur yn addas ar gyfer gyriant 12V DC. Mae foltedd 24V ar gael hefyd.

Mae'r modur camu hwn wedi cael ei ddefnyddio'n helaeth ym mhob diwydiant oherwydd ei bris rhad a'i berfformiad dibynadwy, ac fe'i cynhyrchir mewn symiau mawr bob blwyddyn.

Mae'r cynhyrchiad cyson yn gwneud ansawdd y modur hwn yn sefydlog iawn ac mae'r pris yn is na moduron eraill.

Mae gyrwyr modur stepper unipolar PM cyffredin yn gallu gyrru'r modur hwn.

Os oes gennych ddiddordeb, mae croeso i chi gysylltu â ni.

Paramedrau

| Foltedd (V) | Gwrthiant(Ω) | Torque tynnu i mewn 100PPS (mN * m) | Torque atal (mN * m) | Amlder tynnu i mewn dadlwytho (PPS) |

| 12 | 40 | ≥198 | ≥78.4 | ≥350 |

| 12 | 100 | ≥166 | ≥78.4 | ≥350 |

| 24 | 130 | ≥147 | ≥78.4 | ≥350 |

| 24 | 400 | ≥168 | ≥78.4 | ≥350 |

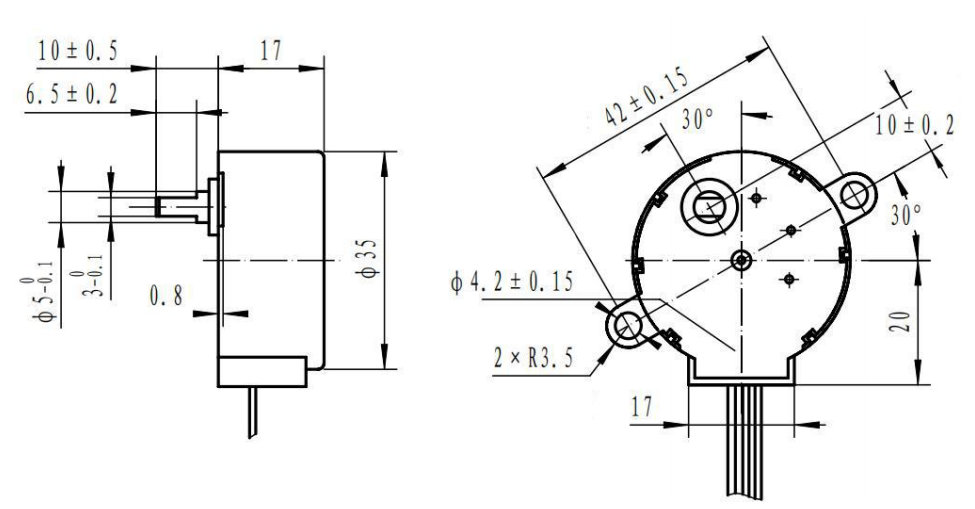

Lluniad dylunio: Siafft allbwn addasadwy

Eitemau addasadwy

Cymhareb gêr,

Foltedd: 5-24V,

Cymhareb gêr,

Deunydd gêr,

Siafft allbwn,

Dyluniad cap y modur yn addasadwy

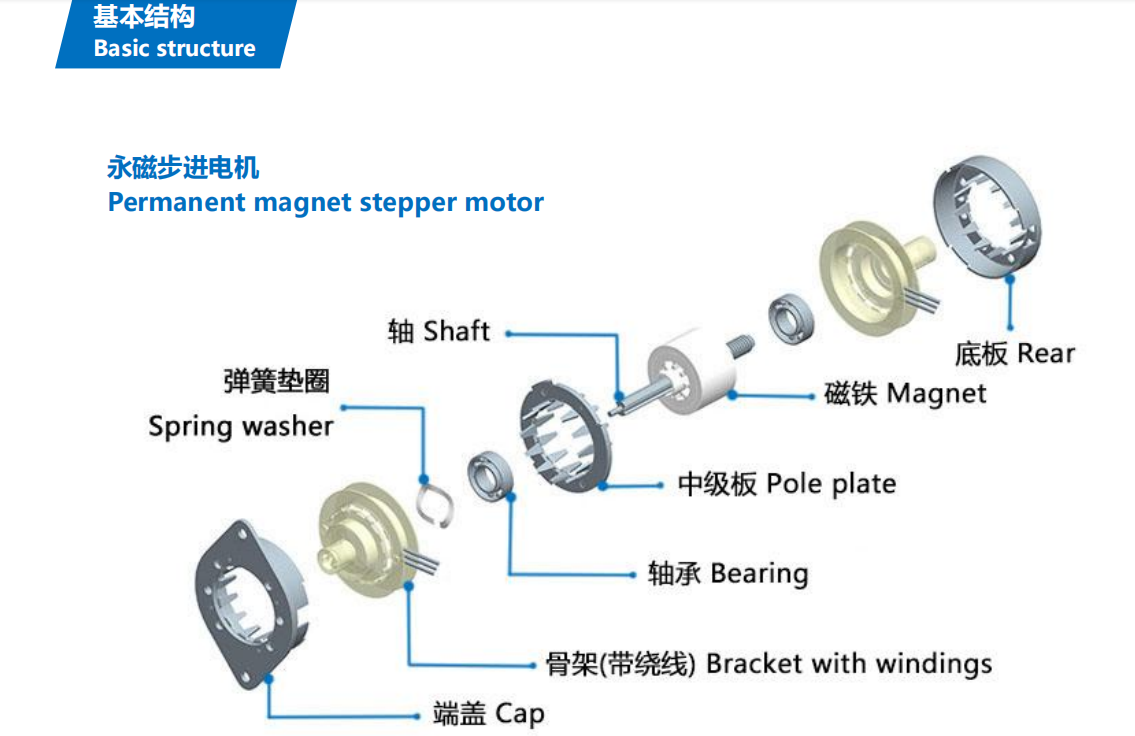

Ynglŷn â strwythur sylfaenol modur stepper PM

Nodweddion a Mantais

1. Lleoli manwl gywirdeb uchel

Gan fod stepwyr yn symud mewn camau ailadroddadwy manwl gywir, maent yn rhagori mewn cymwysiadau sy'n gofyn am fanwl gywir

lleoli, yn ôl nifer y camau y mae'r modur yn symud

2. Rheoli cyflymder Manwl Uchel

Mae cynnydd manwl gywir o symudiad hefyd yn caniatáu rheolaeth ragorol ar gyflymder cylchdro ar gyfer proses

awtomeiddio a roboteg. Mae'r cyflymder cylchdro yn cael ei bennu gan amlder y pylsau.

3. Swyddogaeth oedi a dal

Gyda rheolaeth y gyriant, mae gan y modur swyddogaeth cloi (mae cerrynt trwy weindiadau'r modur, ond

nid yw'r modur yn cylchdroi), ac mae allbwn trorym daliadol o hyd.

4. Bywyd hir ac ymyrraeth electromagnetig isel

Nid oes gan y modur stepper frwsys, ac nid oes angen ei gymudo gan frwsys fel modur wedi'i frwsio.

Modur DC. Nid oes ffrithiant i'r brwsys, sy'n cynyddu'r oes gwasanaeth, nid oes ganddo wreichion trydan, ac mae'n lleihau ymyrraeth electromagnetig.

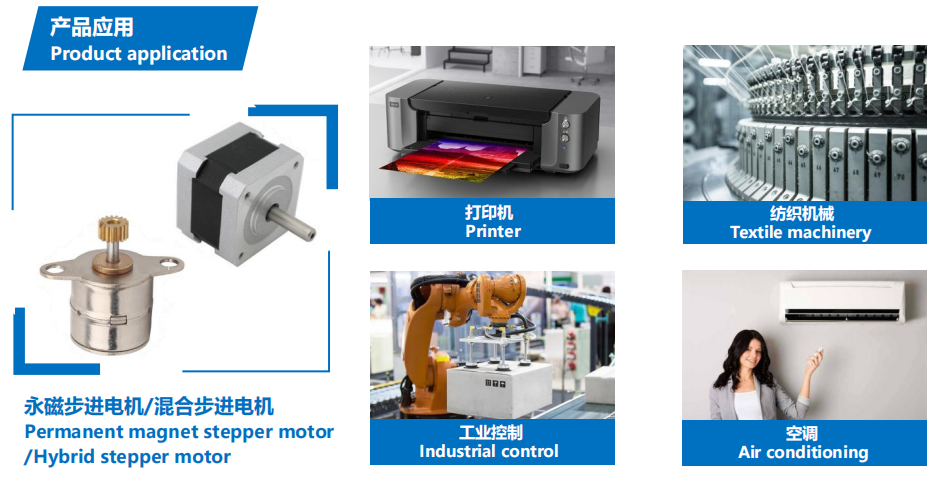

Cymhwyso modur camu PM

Argraffydd,

Peiriannau tecstilau,

Rheolaeth ddiwydiannol,

offer glanweithiol,

falf thermostatig,

tapiau dŵr poeth,

Addasiad awtomatig o dymheredd y dŵr

Cloeon drysau

Aerdymheru

Falf puro dŵr, ac ati.

Egwyddor gweithio modur stepper

Mae gyriant y modur camu yn cael ei reoli gan feddalwedd. Pan fydd angen i'r modur gylchdroi, bydd y gyriant yn...

cymhwyso pylsau'r modur camu. Mae'r pylsau hyn yn rhoi egni i'r moduron camu mewn trefn benodol, a thrwy hynny

gan achosi i rotor y modur gylchdroi i gyfeiriad penodol (clocwedd neu wrthglocwedd). Er mwyn

sicrhau bod y modur yn cylchdroi'n iawn. Bob tro y bydd y modur yn derbyn pwls gan y gyrrwr, bydd yn cylchdroi ar ongl gam (gyda gyriant cam llawn), ac mae ongl cylchdro'r modur yn cael ei phennu gan nifer y pwls sy'n cael eu gyrru a'r ongl gam.

Amser Arweiniol

Os oes gennym samplau mewn stoc, gallwn anfon samplau allan o fewn 3 diwrnod.

Os nad oes gennym samplau mewn stoc, mae angen i ni eu cynhyrchu, mae amser cynhyrchu tua 20 diwrnod calendr.

Ar gyfer cynhyrchu màs, mae'r amser arweiniol yn dibynnu ar faint yr archeb.

Pecynnu

Mae samplau wedi'u pacio mewn sbwng ewyn gyda blwch papur, wedi'u cludo gan express

Cynhyrchu màs, mae moduron wedi'u pacio mewn cartonau rhychog gyda ffilm dryloyw y tu allan. (llongau yn yr awyr)

Os caiff ei gludo ar y môr, bydd y cynnyrch yn cael ei bacio ar baletau

Dull talu a thelerau talu

Ar gyfer samplau, yn gyffredinol rydym yn derbyn Paypal neu alibaba.

Ar gyfer cynhyrchu màs, rydym yn derbyn taliad T/T.

Ar gyfer samplau, rydym yn casglu taliad llawn cyn cynhyrchu.

Ar gyfer cynhyrchu màs, gallwn dderbyn rhagdaliad o 50% cyn cynhyrchu, a chasglu'r gweddill o 50% cyn ei gludo.

Ar ôl i ni gydweithredu archebu mwy na 6 gwaith, gallem drafod telerau talu eraill fel A/S (ar ôl gweld)

Cwestiwn Cyffredin

1. Achosion ac atebion ar gyfer moduron stepper sy'n cwblhau cyflymiad ond yn rhoi'r gorau i gylchdroi pan fyddant yn cyrraedd cyflymder sefydlog.

Achos: Mae'r modur stepper yn rhedeg ar ei derfyn capasiti ac yn stopio oherwydd cyflymiad gormodol. Mae'r rotor yn dirgrynu ac yn rhedeg yn ansefydlog.

Datrysiad.

① Lleihau'r cyflymiad, h.y. dewis cyflymiad is neu ddefnyddio dau lefel cyflymiad gwahanol, yn uwch ar y dechrau ac yn is ger y cyflymder uchaf.

②Cynyddu'r trorym

③Ychwanegwch damper mecanyddol i'r siafft gefn, ond mae hyn yn cynyddu inertia'r rotor

④Ewch ar daith israniad